A Tool For Maintaining your Wheel Assembly

The stud cleaner and pre-torque surface prep kit

The SC100 Stud Cleaner quickly and easily removes foreign particles from wheel studs. Whether it’s road grime or stubborn rust, the tool’s three carbon steel brushes engage the stud’s full thread, providing a clean surface for the wheel retaining nut and allowing for a precise final torque.

Why It Matters

It’s just another tool. . . right?

TIA RIST procedure

The RIST procedure covers the steps to Remove debris from mating surfaces, Inspect all components, Snug the lug nuts in a star pattern, and Torque fasteners to specifications. The SC100 tool helps with the “R” and “I” in the RIST Procedure. The following procedures address the proper mounting of wheel and tire assemblies according to standard recommended practices from the Tire Industry Association (TIA) and the Technology and Maintenance Council (TMC R222C) of the American Trucking Association. This program does not address axle, hub and wheel end maintenance, all of which may contribute to unsafe conditions. The Tire Toolz SC100 Kit has all the items necessary to quickly and efficiently complete the TIA RIST procedure.

Step 1

Remove lug nuts. Use the SC100 Stud Cleaner to remove rust and road tar from studs. Inspect for worn, stretched, and corroded studs.

Step 2

Clean hub mounting surface to remove rust and debris. Assure that mounting pads are clean and undamaged.

Step 3

Remove surface rust, corrosion and any foreign material from mating surfaces and components.

Step 4

Examine rims and other components for surface damage and nicks. Inspect stud holes for those that are oversized, elongated, worn and distorted.

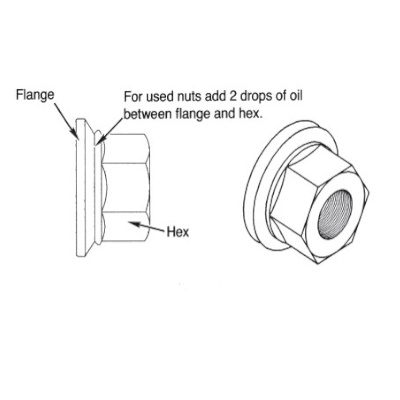

Step 5

Lubricate hub pilot nuts by applying two drops of 30w oil. In addition, for each stud, apply two drops of oil to the last two or three threads.

DO NOT lubricate the hub face, wheel face, or brake drum. Important to avoid excessive lubricant.

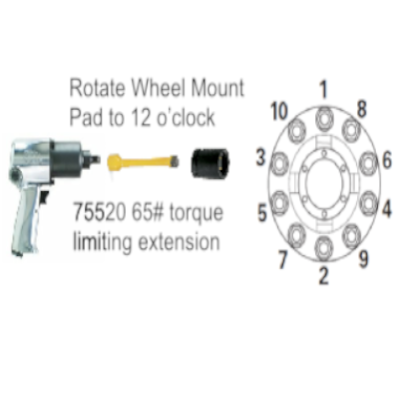

Step 6

Torque all wheel nuts to Manufacturer’s specifications. Use a “star pattern” when tightening lug nuts.

It is not recommended to use an impact drill to fully tighten lug nuts. Instead, use a torque tool/wrench to finish tightening.

WARNING: Wheels, studs, nuts and hubs that are not properly installed, inspected or maintained may not be safe. Recommended to replace altered components. Failure to follow proper installation or maintenance practices may result in injury or death. Always use proper personal protection devices for safety and to avoid injury.

Tire Toolz SC100 Kit

Available, Contact Us Now!

For more information on fleet safety, proper torque procedures and our fleet shop products catalog please fill out and submit the info request form below. One of our customer service specialists will contact you.

Information Request

Dallas

Denver

Atlanta

Albuquerque

Salt Lake City

DENVER

1140 S Jason St, Denver, CO 80223

SALT LAKE CITY

1101 S 700 W, Salt Lake City, UT 84104

ALBUQUERQUE

4412 Prospect Ave NE, Albuquerque, NM 87110

DALLAS

8504 Chancellor Row, Dallas, TX 75247

ATLANTA

3922 Shirley Dr, Atlanta, GA 30336